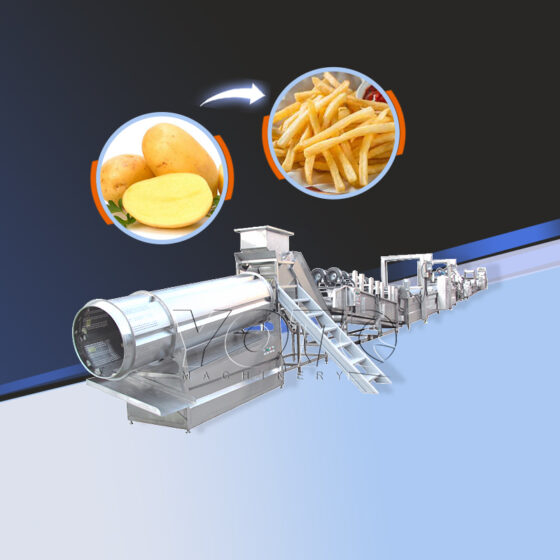

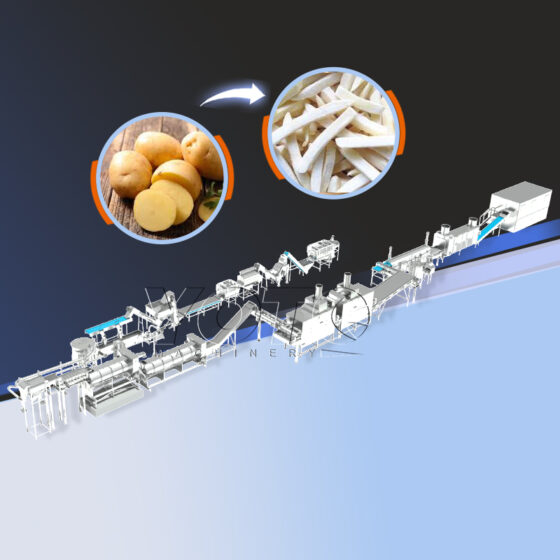

This yum chips production line consists of lifting feeder — roller cleaning stone removal machine — lifting machine — brush peeling machine — manual selection conveyor belt — quantitative lifting feeder — slicing machine — air bubble cleaning machine — air blown stranding machine – rotary type continuous frying machine – lifting selection conveyor — vibration feeder – roller mixing machine — finished product conveyor –420 type automatic packaging machine — air pressure Mechanism nitrogen machine – metal detector – sealing machine.

- Product Details

- Features

- Application

- Working Process

- Inquiry

- The yum chips production line is efficient, uses less energy, is easy to operate and can be customised.

- The heating method is electric, natural gas, liquefied petroleum gas, diesel oil, heavy oil, methanol, alcohol-based fuel, etc.

- The yum chips thickness can be adjusted.

- The fryer is special designed and quick heating and energy saving, enabling good performance.

1.It is suitable for large and small yum chips, potato chips and other processing workshop. According to your workshop area, we can provide a better solution to improve your production line.

2. It can process all kinds of fruit and vegetables, especially root vegetables.

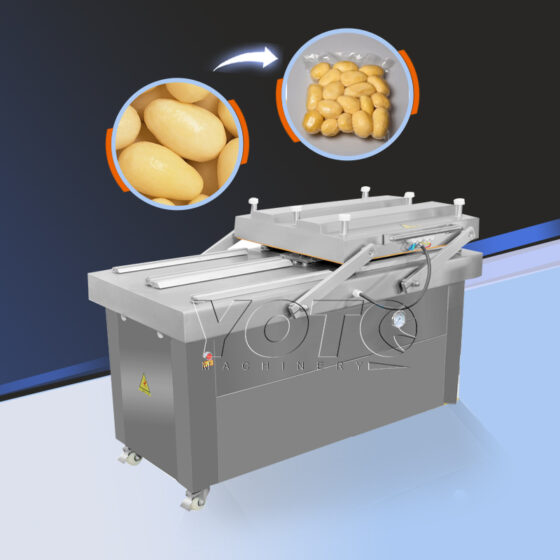

1.Yum Peeling: The process begins with the peeling of the yum. With the help of yum peeling machine, the peels can be effectively removed without damaging the yum flesh.

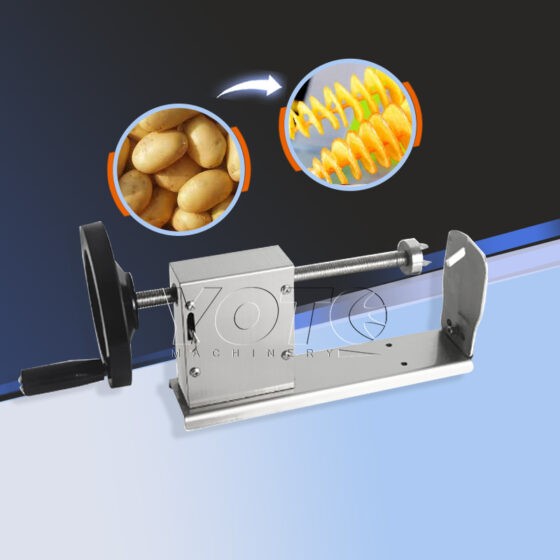

2.Yum Slicing: The peeled yums are sliced into thin, uniform slices by the slicing machine. Our slicer has the features of smooth surface, fast cutting, easy cleaning and simple operation, which can save manpower and cost.

3.Blanching: Blanching is a necessary procedure. Put the yum slices into the blanching machine with a water temperature of about 65-90℃, which can destroy the enzyme activity, improve and soften the tissue structure, make it easy to dry, and also prevent frying and foaming.

4.Dewatering: Processed yum slices need to be drained, using a dehydrator to remove excess moisture and make them easier to fry.

5.Frying: The frying time is 2-3 minutes and the frying temperature is 170-180℃. The dried yum slices are deep-fried in oil at controlled temperatures until they become crispy and golden brown.

6.Seasoning: After frying, the chips can be seasoned with various flavors such as salt, spices, or other flavorings. This can be achieved through a star anise seasoning machine.

7.Packaging: The final step is to package the banana chips into bags, pouches, or containers. 420 type automatic packaging machinery ensures proper sealing and protection of the product to maintain freshness and extend shelf life.

Potato frying machines and production line

Potato frying machines and production line

×

×

WeChat

Scan the QR Code with wechat