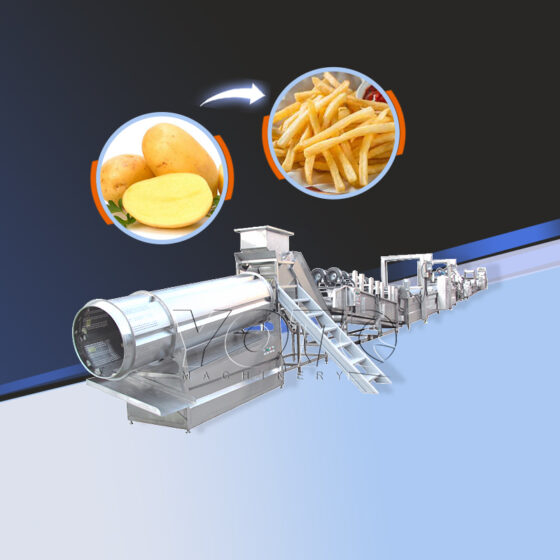

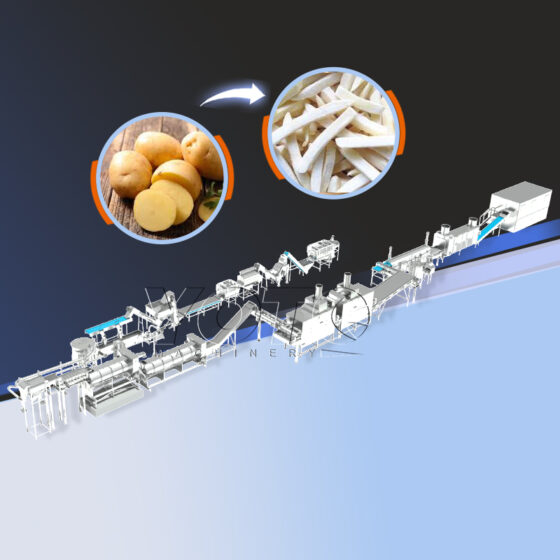

This potato chips production line consists of lifting feeder — roller cleaning stone removal machine — lifting machine — brush peeling machine — manual selection conveyor belt — quantitative lifting feeder — slicing machine — air bubble cleaning machine — air blown stranding machine – rotary type continuous frying machine – lifting selection conveyor — vibration feeder – roller mixing machine — finished product conveyor –420 type automatic packaging machine — air pressure Mechanism nitrogen machine – metal detector – sealing machine.

- Product Details

- Features

- Application

- Working Process

- Inquiry

- The potato chips production line is efficient, uses less energy, is easy to operate and can be customised.

- The heating method is electric, natural gas, liquefied petroleum gas, diesel oil, heavy oil, methanol, alcohol-based fuel, etc.

- The potato chips thickness can be adjusted.

- The fryer is special designed and quick heating and energy saving, enabling good performance.

- The machine is suitable for large and small potato chips, banana chips and other processing workshops. We can provide a better solution to improve your production line according to your workshop area.

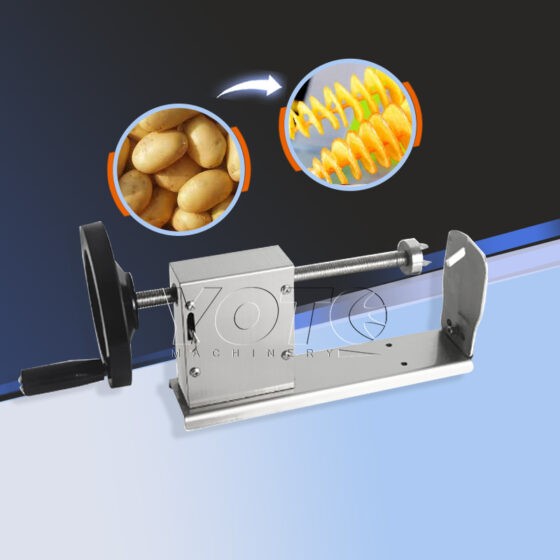

- The machine can process all kinds of fruit and vegetables, especially root vegetables.

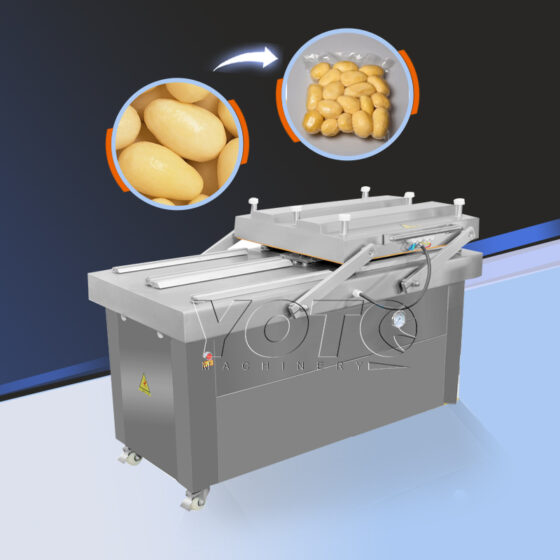

- Washing and peeling: The potatoes are cleaned and peeled. This removes dirt and the outer skin.

- Slicing: The peeled potatoes are sliced into thin, uniform slices. This ensures even frying and consistent quality. Our slicer has a smooth surface, fast cutting, easy cleaning and simple operation, which can save manpower and cost.

- Air bubble cleaning: The cleaning time is 30-40S. During the cleaning process, the starch and sugar on the surface of potato chips can be removed to prevent the deterioration of the oil body and prolong the service life of the oil.

- Blanching: Blanching is a necessary procedure. Put the potato slices into the blanching machine with water at about 65-90℃. This softens the potato slices and makes them easy to dry.

- Drying: Drying the potato slices reduces the oil content during frying. This improves the taste and reduces energy consumption.

- Frying: Fry for 2-3 minutes at 170-180℃. Deep-fry the dried potato slices in oil until they are crispy and golden brown.

- Seasoning: Season the chips with salt, spices, or other flavourings after frying. This can be done with a seasoning drum machine.

- Packaging: The final step is to put the chips into bags, pouches or containers. Automatic packaging machinery ensures the product is sealed and protected to keep it fresh and extend its shelf life.

Potato frying machines and production line

Potato frying machines and production line

×

×

Machine potato chips production

Quiero recibir información de la máquina