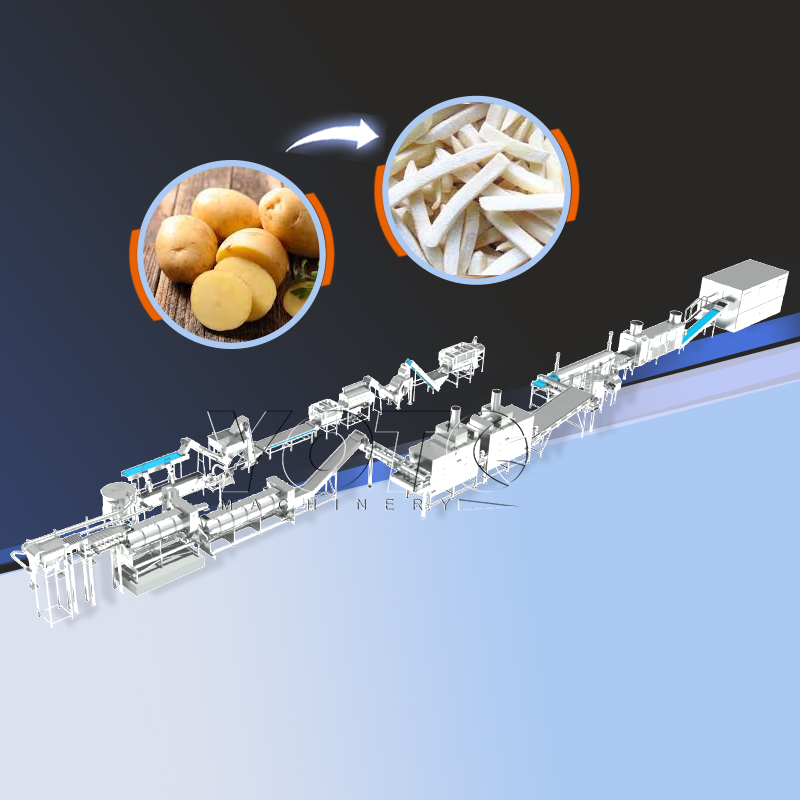

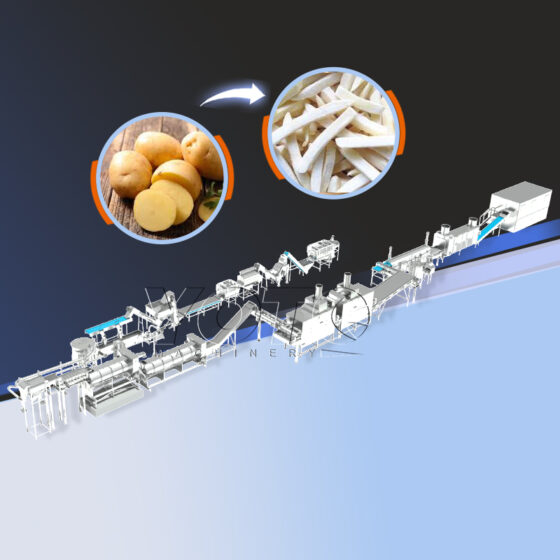

The frozen French fry production line comprises a series of integrated processes, including lifting and conveying, cleaning and peeling, manual picking, lifting and dividing, cutting, bubble cleaning, vibration draining, air drying draining, frying, vibration deoiling, air cooling, quick freezing and packing. These processes offer a number of advantages, including low investment, low energy consumption, multiple functions, small size, high profit and convenient maintenance.

- Product Details

- Features

- Application

- Working Process

- Inquiry

- Precise configuration and control: Maintain optimal working conditions, boost production, and guarantee consistent product quality.

- Stainless steel design: The frame structure is crafted from stainless steel, which is highly resistant to deformation.

- Integrated design: Reduce the key costs of the production process and streamline it.

- Support customisation: The frozen French fries production line can be customised to meet customers’ specific requirements.

- Our automatic frozen French fries production line is suitable for use in a variety of food processing facilities, including frozen food factories, snack food factories, and fruit and vegetable processing plants.

- The line is capable of processing a wide range of fruits and vegetables, with a particular focus on root vegetables.

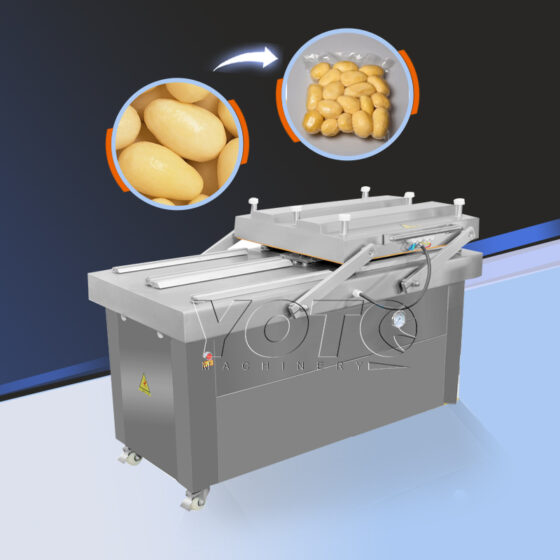

- Washing and peeling: Use a roller cleaning stone removal machine and brush peeling machine to remove dirt and the outer skin of the potatoes.

- Cutting: Cut the peeled potatoes into French fries with a cutting machine. Adjust the thickness of the French fries.

- Cleaning: The cleaning time is 30-40 s. Cleaning removes starch and sugar from French fries, preventing oil deterioration and extending oil life.

- Blanching: Blanching is essential. Put the French fries into the blanching machine with water at 65-90℃. This softens the fries and makes them easier to dry.

- Drying: Drying the French fries reduces the oil content during frying, improving taste and reducing energy consumption.

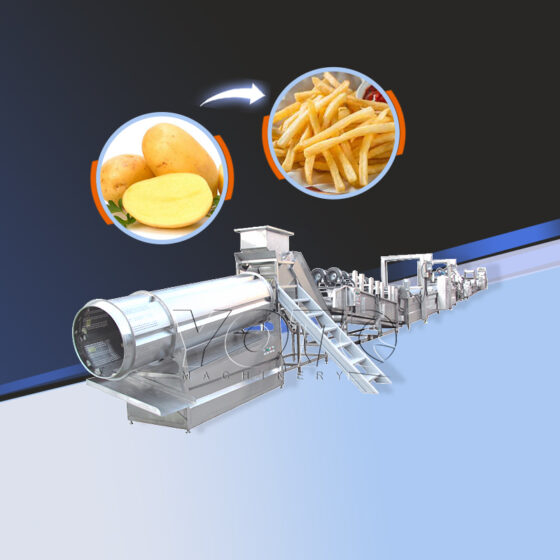

- Frying: The frying time is 2-3 minutes and the frying temperature is 170-180℃. The French fries are deep-fried in oil at controlled temperatures until they become crispy and golden brown.

- Freezing: After frying, the French fries are sent to a freezing machine. This can extend the shelf life of French fries.

- Packaging: The final step is to package the French fries into bags, pouches, or containers. 420 type automatic packaging machinery ensures proper sealing and protection of the product to maintain freshness and extend shelf life.

Potato frying machines and production line

Potato frying machines and production line

×

×

WeChat

Scan the QR Code with wechat