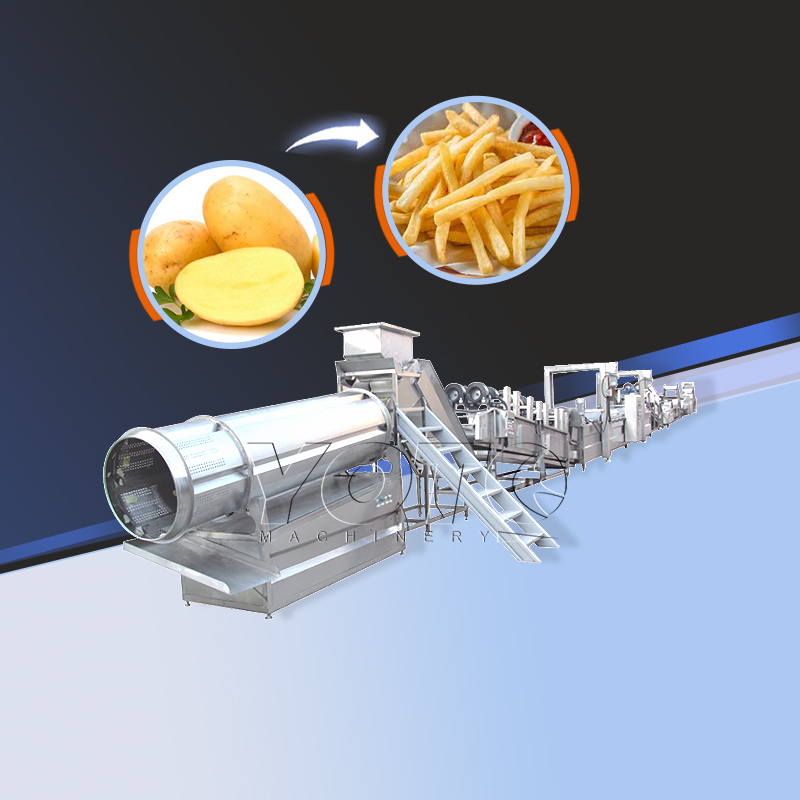

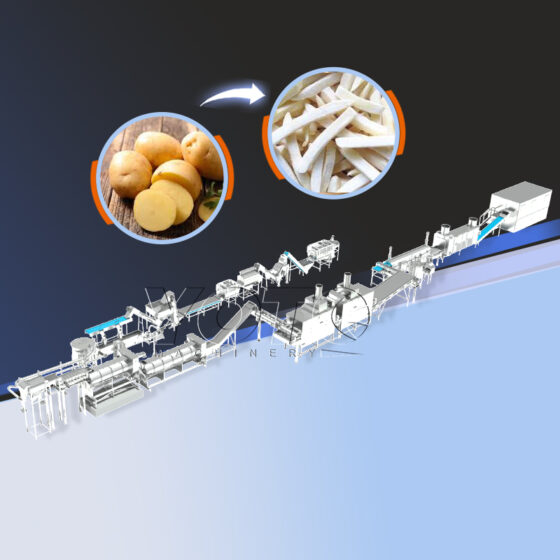

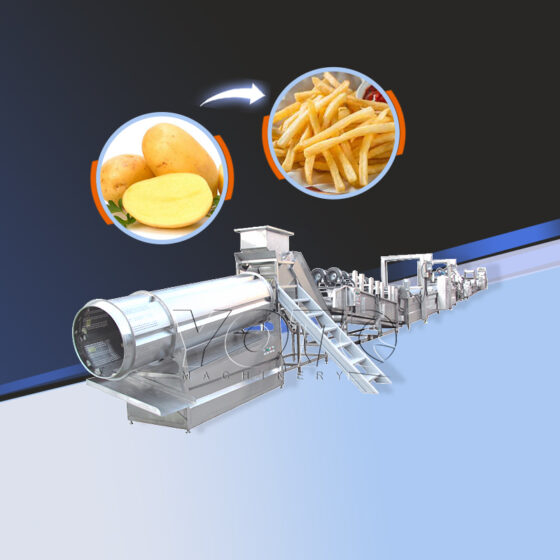

This French fries production line has been designed to handle various stages of the manufacturing process, from raw potatoes to the final packaged French fries ready for distribution and consumption. The line is mainly composed of a lifting feeder, a roller cleaning stone removal machine, a brush peeling machine, a cutting machine, an air bubble cleaning machine, a rotary-type continuous frying machine, a drum seasoning machine and a 420-type automatic packaging machine.

- Product Details

- Features

- Application

- Working Process

- Inquiry

- French fries can be made thinner or thicker.

- The fryer can be heated by electricity, gas, diesel, methanol, alcohol, etc.

- The special fryer heats and saves energy, so it works well.

- It is very efficient. Making French fries in a factory is more efficient than making them by hand.

- It is easy to maintain. Our machines are designed and manufactured in innovative ways. This makes it easy to do maintenance work with less downtime, while ensuring the safety of the final product.

- Customised turnkey solutions. A suitable production line is key to successful French fries making. With experience and professional engineers, we can offer customised solutions for your French fries line.

- Our automatic French fries production line is suitable for industrial production. Whether you require a new line with high production capacity or wish to enhance the capacity of your existing line, we are able to assist as an experienced manufacturer.

- It can process a wide range of fruit and vegetables, including root vegetables.

- Elevator: Used for lifting and conveying material. Potatoes can be poured into the hopper manually and lifted to the next process through the conveyor belt, saving labour and being convenient and practical.

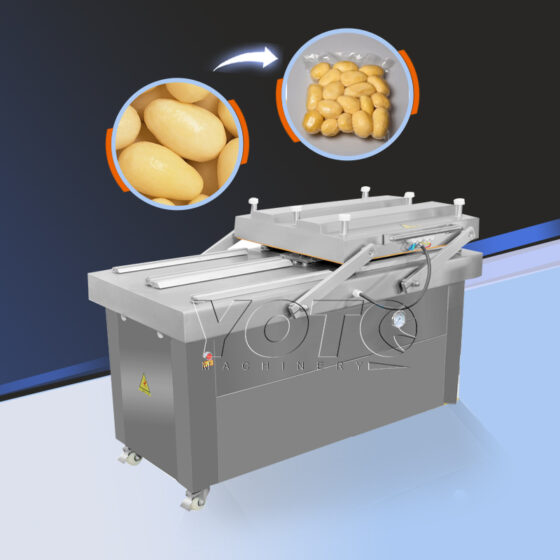

- Cleaning and peeling machine: Potatoes can be cleaned and peeled and materials fed and discharged at the same time, working continuously.

- Picking belt: To pick and repair the cleaned and peeled potatoes. Bad ones need to be picked out.

- Potato cutter machine: Put the peeled and clean potatoes into the feeding port and the French fries will be cut out.

- Rinsing machine: Wash the French fries.

- Blanching machine: Blanch and add food additives to French fries.

- Cooling machine: Cool the blanched French fries to prevent sticking.

- Air-cooled dehydrator: Dry the surface of the blanched French fries for frying.

- Frying machine: Fry the French fries. The temperature can be controlled and it can work continuously.

- Deoiling machine: Take off the oil from the fried French fries.

- Picking belt: Blow the French fries to cool for packaging.

- Seasoning machine: Season the selected French fries.

- Packing machine: Pack the French fries.

Potato frying machines and production line

Potato frying machines and production line

×

×

WeChat

Scan the QR Code with wechat